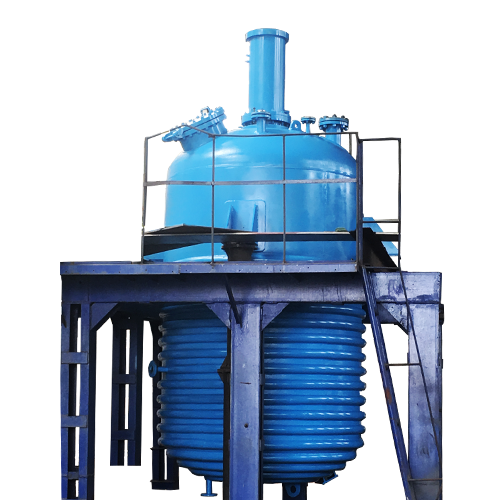

Industrial Reactor

Your Current Location:Home > Product Center > Industrial ReactorThe semi-circular coil jacket is an efficient heat transfer element. Compared with other forms of jacket, the heat transfer efficiency is high; compared with the inner coil, there is no risk of mixing with the medium in the tank after the leakage of the coil, so it is often used in occasions where the purity of the medium is relatively high.

Semi-circular coils are limited to use seamless tubes with outer diameters of 60, 89, 114mm, suitable for vessels with a diameter of 760~4300mm, and a cylinder or head thickness of 4.5~50mm.

When the semicircular coil jacket is arranged on the shell, its pitch can be determined according to the needs of the heat transfer process and the welding process, and has nothing to do with the strength and rigidity of the shell. Therefore, the semicircular coil jacket does not need to calculate the external pressure, and it has a certain strengthening support for the kettle body.

Stainless steel is often divided into martensitic steel, ferritic steel, austenitic steel, austenitic-ferritic (duplex) stainless steel and precipitation hardening stainless steel according to the state of organization. In addition, it can be divided into: chromium stainless steel, chromium nickel stainless steel and chromium manganese nitrogen stainless steel.

The body, cover and contact materials in the stainless steel reactor are mainly made of 0Cr18Ni9 (S30408), 00Cr17Ni14Mo2 (S31603), 0Cr18Ni10Ti (S32168), or 2205, 2507 and other materials.

Stainless steel has good corrosion resistance and can withstand a variety of acids, alkalis and organic media. The inner and outer surfaces can be pickled and passivated according to the needs of customers to form an oxide film and strengthen the anti-corrosion function. For the inner surface of the kettle with polishing requirements, it can reach the level of mirror polishing.

Hastelloy is a nickel-based corrosion-resistant alloy, mainly divided into two categories: nickel-chromium alloy and nickel-chromium-molybdenum alloy. Hastelloy has good corrosion resistance and thermal stability. Hastelloy plates are suitable for various chemical industries containing oxidizing and reducing media. The higher content of molybdenum and chromium makes the alloy resistant to chloride ion corrosion, and the tungsten element further improves the corrosion resistance. At the same time, C-276 Hastelloy tube is one of the only materials that are resistant to corrosion by moist chlorine, hypochlorite and chlorine dioxide solutions. It is effective for high-concentration chloride solutions such as ferric chloride and copper chloride. Significant corrosion resistance.

The commonly used Hastelloy grades for the reactor are HASTELLOY B2 and HASTELLOY C276. The price of Hastelloy alloy materials is relatively high. In order to save costs, pressure vessels often use explosive composite plates of Hastelloy liner and carbon steel or stainless steel substrate. The substrate meets the requirements for strength and the liner meets the requirements for corrosion resistance.

Heavy non-ferrous metal materials composed of nickel-based and other alloying elements are nickel-based alloys. The grade of nickel used in the reactor is N6. Commonly used nickel-based alloy materials are Monel (MONEL400), Inconel (INCONEL600, INCONEL625), Hastelloy (HASTELLOY C276, HASTELLOY B2), etc.

Nickel-based materials are better than stainless steel in high temperature resistance, high pressure resistance and corrosion resistance, so they are more suitable for harsh reaction media and reaction conditions.

The cost of nickel-based and nickel-based materials is relatively high. Therefore, the explosive composite plate of nickel-based and nickel-based alloy liner and stainless steel or carbon steel substrate is commonly used in industrial production of pressure vessels. The substrate meets the requirements of strength and the liner meets the requirements of corrosion resistance.

The open-type flat-lid structure reactor has two types: flat end flange type and flat cover reverse flange type. The design concepts of these two structures are basically the same, but the flat cover reverse flange type is more expensive than flat cover. The flange type of the cover end is cheaper. The design concept is based on certain chemical products that require higher pressure (4.0-35Mpa) during the production process, without too much restriction on temperature, and small volume (below 3000L). Because the open structure is more convenient for equipment maintenance and disassembly, especially for highly toxic and flammable chemical products, this structure can improve the working environment of workers and reduce their labor intensity. Because this structure is suitable for higher pressure and the barrel is thicker, the processing cycle is longer.

The crystallization reactor is used in the production process of forced cooling and crystallization in the production process of chemical products.

In the chemical industry, for example, in the production process of tetrabutylammonium bromide, the reactants need to be forced to cool and crystallize in the crystallization reactor. The crystallization reactor has a cylindrical barrel and a conical bottom, a cylindrical barrel and a cone. The bottom of the shaped cylinder has a double cylinder wall, and the cooling liquid inlet and outlet cavity is formed in the middle of the double cylinder wall, and the medium in the crystallization reaction kettle is forcedly cooled by the cooling liquid to make it crystallize. Some processes use inner coils and nitrogen to cool the contents of the kettle.

The powerful agitator is equipped with a wall scraping structure, which can effectively drive the materials adhered to the wall of the kettle to make the reaction more fully and evenly.

Generally, at low temperatures, conventional rock wool insulation is used outside the jacket. For lower temperatures, a vacuum insulation jacket is added outside the refrigeration jacket to isolate the air heat transfer and continuously maintain the low temperature in the kettle.